ROCK

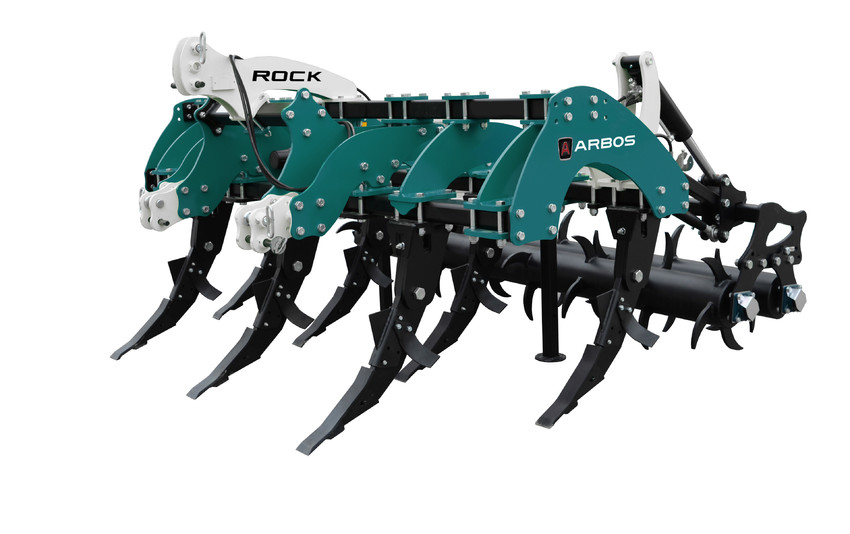

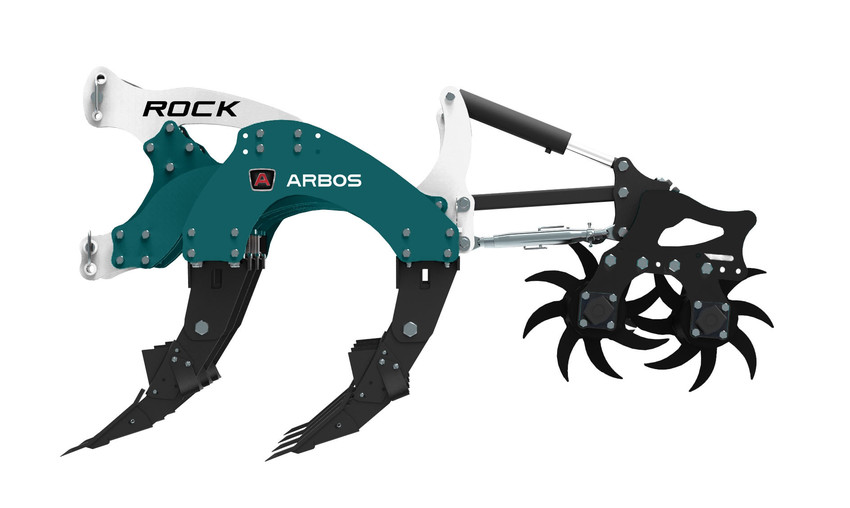

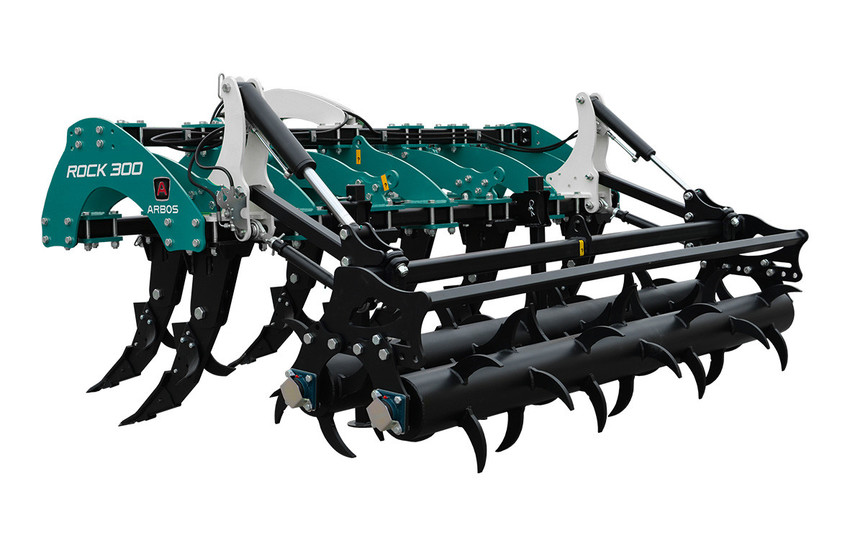

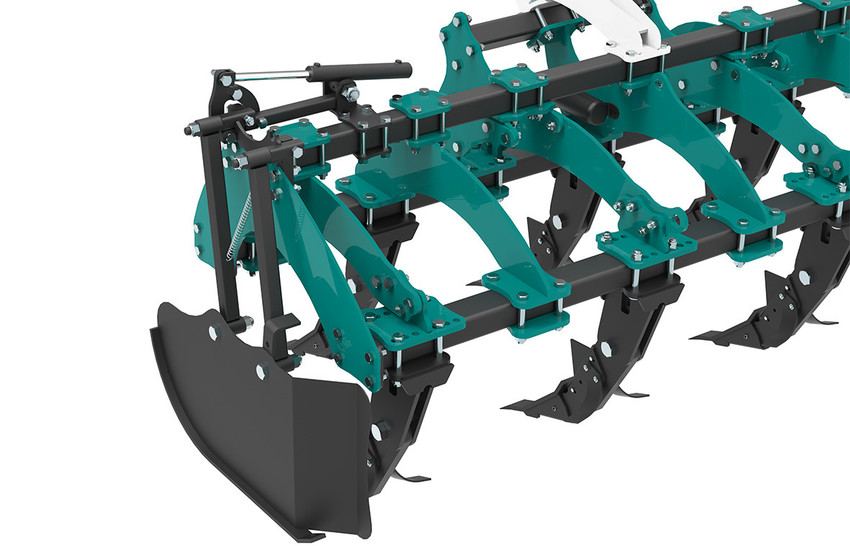

The ARBOS ripper of the ROCK series has been designed and constructed to meet all user needs on particularly firm terrain and where crop residue is present. The high resistant steel used and the particular structure with bolted joints make the ROCK ripper suitable for heavy-duty working conditions. Each anchor is equipped with a bolted safety device duly sized and a quickrelease tip. It can also be equipped with deflectors to break up the terrain better.

The row spacing between the anchors can be easily modified to adapt to the needs of the most demanding operator. The ROCK ripper can also be used in the version without wheels. The rear rollers are equipped with parallelogram hydraulic movement which ensures quick and accurate adjustment of the working depth.

The particular architecture of the roller frame allows the operator to modify the centreline between the roller. This important technical solution allows the machine to be customised so that it adapts perfectly to all conditions of the terrain.

- Hydraulic adjustment of the working depth

- Mechanical adjustment of the roller distance

- Mechanical adjustment of the roller alignment

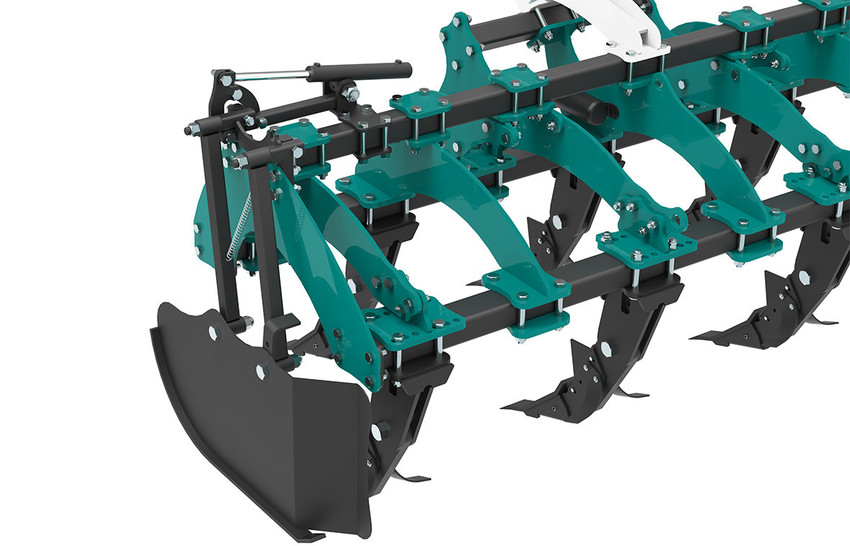

Deflectors

The steel deflectors with anti-wear treatment can be adjusted and set to one of two positions to adapt to all types of terrain.

The steel deflectors with anti-wear treatment can be adjusted and set to one of two positions to adapt to all types of terrain.

Joints

Joints using a locking system with high-resistant bolts.

Joints using a locking system with high-resistant bolts.

Anchors

The anchors are equipped with a bolted safety device.

The anchors are equipped with a bolted safety device.

Long Life Tips

The tips are in anti-wear steel and can be easily replaced thanks to a quick-fit disassembly system.

The tips are in anti-wear steel and can be easily replaced thanks to a quick-fit disassembly system.

Technical features

| RIPPERS | 5 |

| WORKING DEPTH | 55 cm |

| TOOL BAR | 250 cm |

| RIPPER ROWS DISTANCE | 80 cm |

| WEIGHT BASE | 940 Kg |

| WEIGHT RULLER | 1390 kg |

| POWER REQUIRED BASE | 130-170 hp |

| POWER REQUIRED MAX | 200 hp |

| RIPPERS | 7 |

| WORKING DEPTH | 55 cm |

| TOOL BAR | 250 cm |

| RIPPER ROWS DISTANCE | 80 cm |

| WEIGHT BASE | 1150 Kg |

| WEIGHT RULLER | 1600 kg |

| POWER REQUIRED BASE | 150-220 hp |

| POWER REQUIRED MAX | 250 hp |

| RIPPERS | 5 |

| WORKING DEPTH | 55 cm |

| TOOL BAR | 300 cm |

| RIPPER ROWS DISTANCE | 80 cm |

| WEIGHT BASE | 980 Kg |

| WEIGHT RULLER | 1480 kg |

| POWER REQUIRED BASE | 130-170 hp |

| POWER REQUIRED MAX | 200 hp |

| RIPPERS | 7 |

| WORKING DEPTH | 55 cm |

| TOOL BAR | 300 cm |

| RIPPER ROWS DISTANCE | 80 cm |

| WEIGHT BASE | 1170 Kg |

| WEIGHT RULLER | 1670 Kg |

| POWER REQUIRED BASE | 150-220 hp |

| POWER REQUIRED MAX | 250 hp |

| RIPPERS | 5 |

| WORKING DEPTH | 65 cm |

| TOOL BAR | 250 cm |

| RIPPER ROWS DISTANCE | 87 cm |

| WEIGHT BASE | 1400 Kg |

| WEIGHT RULLER | 2040 kg |

| POWER REQUIRED BASE | 150-250 hp |

| POWER REQUIRED MAX | 280 hp |

| RIPPERS | 5 |

| WORKING DEPTH | 65 cm |

| TOOL BAR | 300 cm |

| RIPPER ROWS DISTANCE | 87 cm |

| WEIGHT BASE | 1440 Kg |

| WEIGHT RULLER | 2140 Kg |

| POWER REQUIRED BASE | 150-250 hp |

| POWER REQUIRED MAX | 280 hp |

| RIPPERS | 7 |

| WORKING DEPTH | 65 cm |

| TOOL BAR | 300 cm |

| RIPPER ROWS DISTANCE | 87 cm |

| WEIGHT BASE | 1700 Kg |

| WEIGHT RULLER | 2410 Kg |

| POWER REQUIRED BASE | 200-370 hp |

| POWER REQUIRED MAX | 400 hp |

| RIPPERS | 7 |

| WORKING DEPTH | 65 cm |

| TOOL BAR | 390 cm |

| RIPPER ROWS DISTANCE | 87 cm |

| WEIGHT BASE | 1740 Kg |

| WEIGHT RULLER | 2540 Kg |

| POWER REQUIRED BASE | 200-370 hp |

| POWER REQUIRED MAX | 400 hp |

| RIPPERS | 9 |

| WORKING DEPTH | 65 cm |

| TOOL BAR | 390 cm |

| RIPPER ROWS DISTANCE | 87 cm |

| WEIGHT BASE | 2100 Kg |

| WEIGHT RULLER | 2900 Kg |

| POWER REQUIRED BASE | 250-400 hp |

| POWER REQUIRED MAX | 420 hp |